DIY CNC Milling: What You Need to Know Before Starting

Understanding CNC Milling

CNC milling is a versatile and powerful tool in the world of manufacturing. It allows hobbyists and professionals alike to create precise and complex parts with ease. But before you jump into the exciting world of DIY CNC milling, there are several key factors you need to consider to ensure a successful and fulfilling project.

Essential Equipment

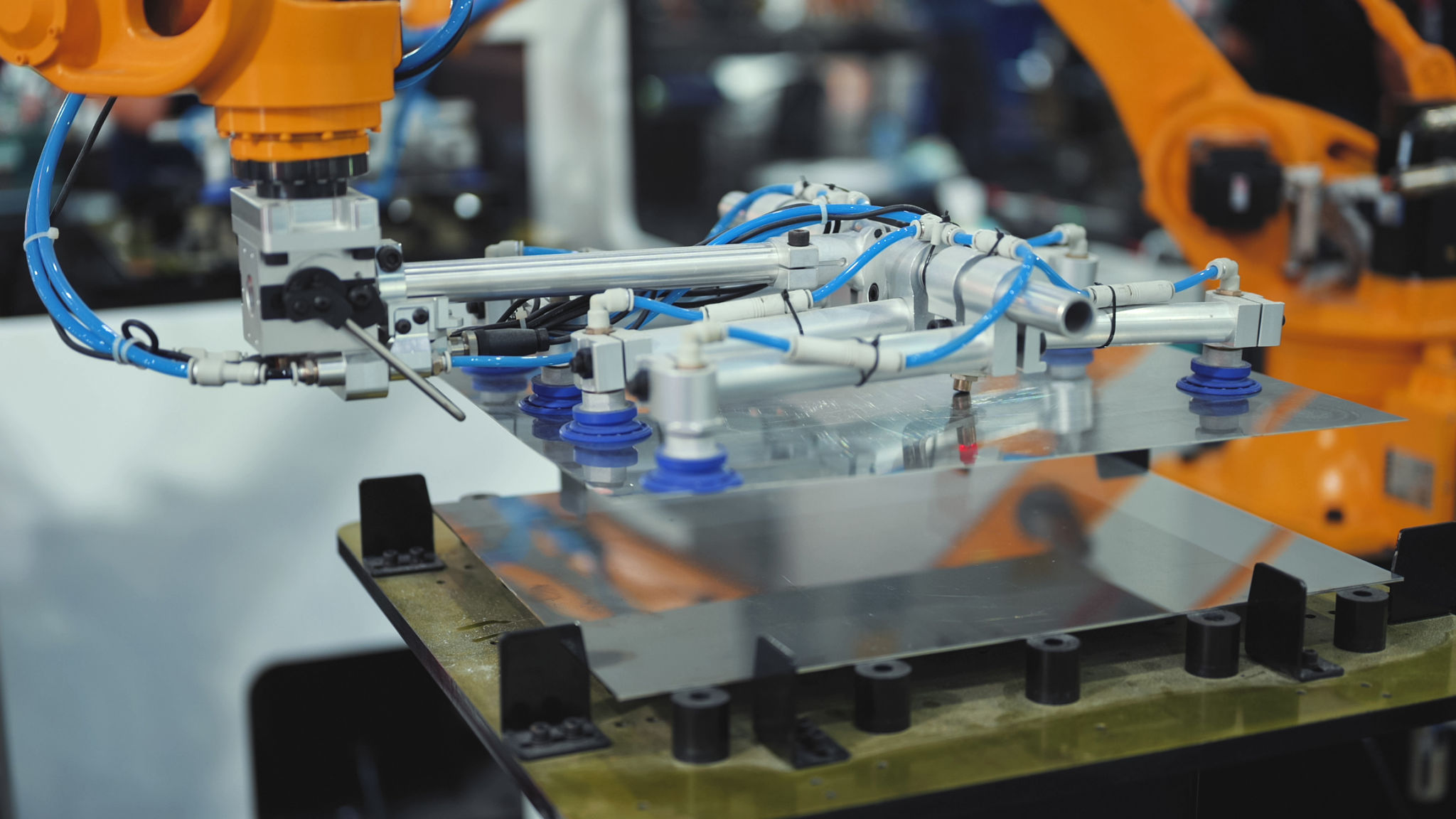

Before starting your CNC milling journey, it's crucial to understand the equipment you'll need. At the core is the milling machine itself, which can range from small desktop models to larger industrial-grade machines. Ensure you choose one that fits your project scope and budget. Additionally, you'll need a computer with CAD/CAM software to design your parts and a controller to manage the milling process.

Other essential tools include end mills for cutting, collets for holding the end mills, and a workholding device to secure your material on the milling bed. Investing in quality tooling can greatly affect the precision and quality of your final product.

Materials and Safety

The choice of materials is another critical aspect of CNC milling. Common materials include wood, plastic, and metals like aluminum and brass. Each material requires different cutting speeds and techniques, so it’s important to research how your chosen material behaves under a milling machine.

Safety should never be overlooked when working with CNC machines. Always wear appropriate protective gear such as safety glasses and hearing protection. Make sure your workspace is well-ventilated and free of clutter to prevent accidents.

Learning the Software

Mastering the software is just as important as understanding the hardware. CAD (Computer-Aided Design) software allows you to create detailed models of your parts, while CAM (Computer-Aided Manufacturing) software translates these models into instructions for your CNC machine.

There are numerous software options available, ranging from free open-source programs to professional-grade applications. Spend time learning the software you choose, as this will directly impact the accuracy and efficiency of your milling projects.

Project Planning and Testing

Before cutting into your final material, it’s wise to conduct test runs using cheaper or scrap material. This allows you to fine-tune your machine settings and catch any errors in your design or execution. Proper planning minimizes waste and increases the likelihood of a successful outcome.

Cost Considerations

CNC milling can be an investment both in terms of time and money. Be sure to account for all costs, including equipment, materials, tools, and software licenses. Setting a realistic budget will help you manage expenses and avoid any unwelcome surprises during your project.

Consider starting with small projects to build confidence before tackling more complex designs. This approach allows you to learn from mistakes without incurring significant costs.

Joining the Community

The CNC community is vast and supportive, offering forums, tutorials, and resources for beginners and experts alike. Engaging with this community can provide valuable insights, tips, and encouragement as you navigate the world of DIY CNC milling.

Whether you're a seasoned machinist or a curious hobbyist, CNC milling opens up a world of possibilities for creativity and innovation. By equipping yourself with the right knowledge and tools, you'll be well on your way to creating precise and intricate designs with your very own CNC machine.