Expert Tips for Ensuring Component Precision with CNC Machining

Understanding the Basics of CNC Machining

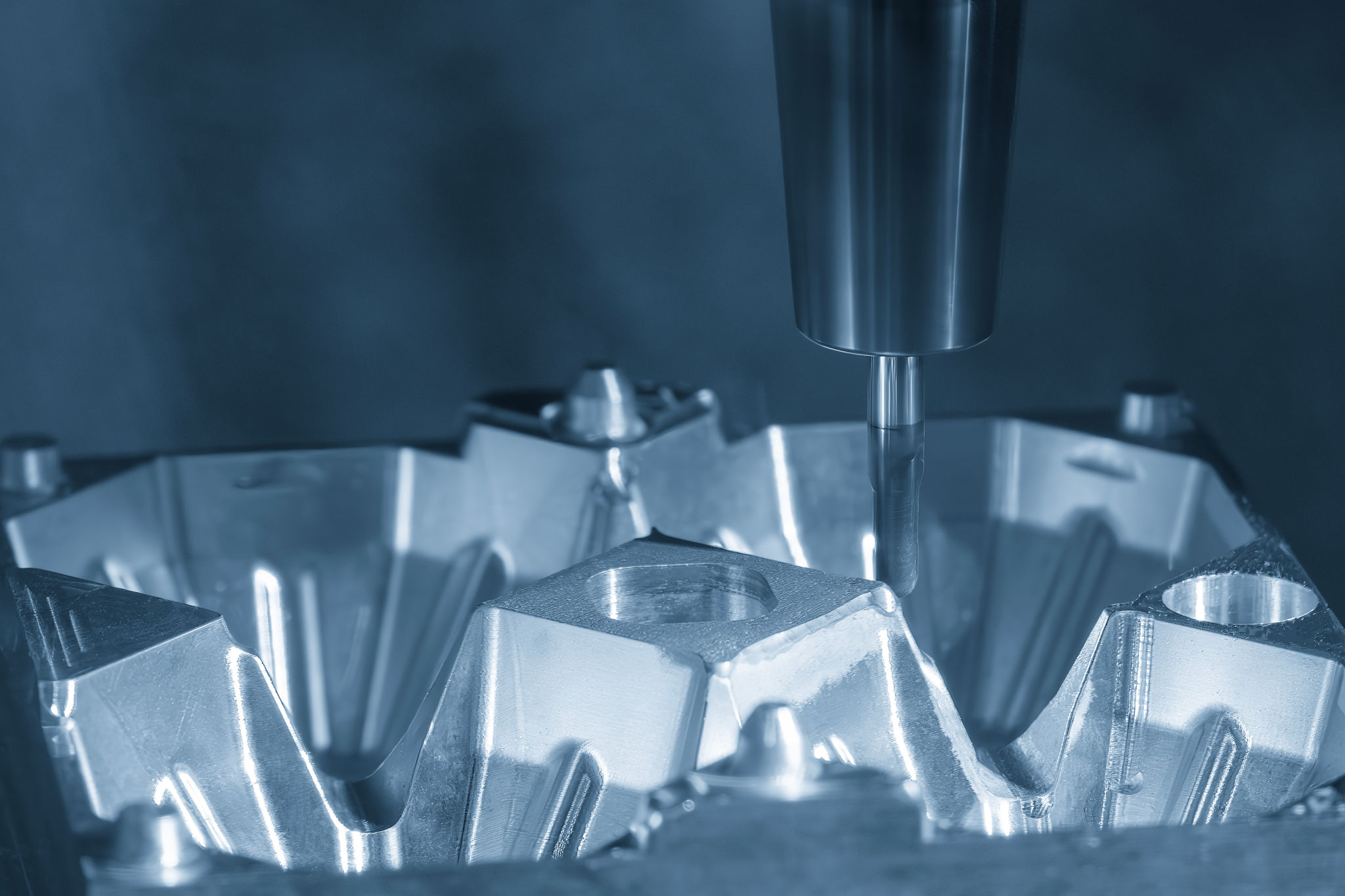

CNC (Computer Numerical Control) machining is a precise manufacturing process that uses computerized controls to operate machinery and tools. It’s widely used in various industries for creating intricate parts and components with high accuracy. Understanding the basic principles of CNC machining is crucial for achieving precision in component manufacturing.

At its core, CNC machining involves the use of CAD (Computer-Aided Design) software to design parts and CAM (Computer-Aided Manufacturing) software to create the necessary instructions for the machine. These instructions, or G-code, guide the machine in executing precise movements to shape the material into the desired form.

Importance of Material Selection

The choice of material is a critical factor in ensuring component precision. Different materials have varying properties, such as hardness, strength, and thermal resistance, which affect how they respond to CNC machining processes. Therefore, selecting the right material for your specific application is essential for achieving the desired precision and performance.

Consider materials like aluminum for lightweight applications, steel for durability, or titanium for high-strength requirements. Each material offers unique advantages and challenges, so it's important to understand their characteristics to optimize machining outcomes.

Optimizing Tool Selection

Tool selection plays a significant role in CNC machining precision. The tools used must match the material properties and the complexity of the design. For instance, carbide tools are excellent for cutting hard materials, while high-speed steel tools are better suited for softer materials.

Regularly inspecting and maintaining cutting tools is also important. Worn or damaged tools can lead to inaccuracies and defects in the final product. Implementing a tool management system can help track tool wear and ensure timely replacements.

Implementing Rigorous Quality Control

Quality control is an essential step in ensuring component precision. Implementing rigorous inspection processes helps identify any deviations from design specifications early in the production process. This can include using coordinate measuring machines (CMM) or laser scanners to verify dimensions and ensure accuracy.

Additionally, conducting regular audits of your CNC processes can help maintain consistency and improve overall quality. Documenting each step and outcome allows for better traceability and helps identify areas for improvement.

Leveraging Software Innovations

Advancements in software technology have greatly enhanced CNC machining precision. Modern software solutions offer advanced simulation capabilities, allowing manufacturers to visualize the machining process before actual production. This helps identify potential issues and optimize tool paths for greater accuracy.

Additionally, integrated monitoring systems can provide real-time feedback during production, enabling immediate adjustments to maintain precision. Embracing these innovations can significantly improve both efficiency and accuracy in CNC machining operations.

Training and Skilled Workforce

Finally, a skilled workforce is vital for ensuring component precision with CNC machining. Operators should be well-trained in understanding machine operations, software use, and quality control practices. Investing in continuous training programs helps keep the workforce updated with the latest technologies and techniques.

Encouraging collaboration between design engineers and machine operators can also enhance understanding and lead to better decision-making throughout the production process.

By focusing on these expert tips, manufacturers can achieve higher precision in CNC machining, leading to superior quality components that meet industry standards and customer expectations.