The Role of Precision Honing in Oil & Gas Component Fabrication

Understanding Precision Honing

Precision honing is a vital process in the fabrication of components for the oil and gas industry. This technique involves the use of abrasive stones to create smooth and precise surfaces on metal parts. The goal is to achieve the desired dimensions and surface finish, which is crucial for the performance and longevity of components.

In the oil and gas sector, where equipment often operates under extreme conditions, precision honing ensures that components can withstand high pressure, temperature fluctuations, and corrosive environments. Its role cannot be underestimated, as even the slightest imperfection can lead to significant operational challenges.

Benefits of Precision Honing in Component Fabrication

The benefits of precision honing in the oil and gas industry are manifold. Firstly, it enhances the wear resistance of components, which is essential for drilling equipment and pipelines that are exposed to continuous friction and abrasion. Secondly, it improves sealing capabilities, reducing the risk of leaks and ensuring safety.

Moreover, precision honing contributes to the overall efficiency of machinery by reducing friction between moving parts. This not only extends the lifespan of the equipment but also minimizes maintenance costs, leading to more reliable operations and reduced downtime.

Key Applications in the Oil & Gas Industry

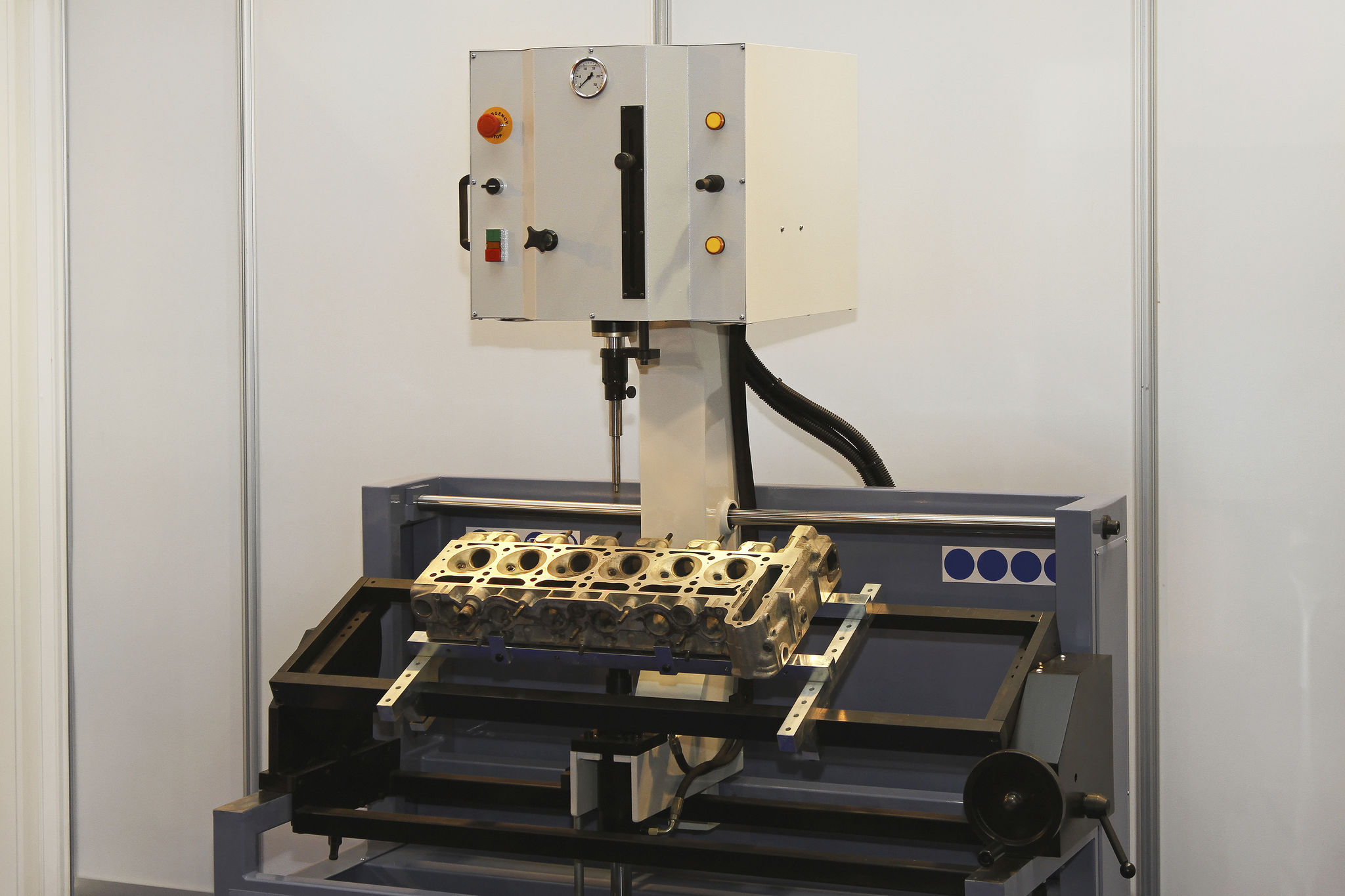

Precision honing is primarily used in the fabrication of components such as hydraulic cylinders, engine parts, and valve bodies. These components require exact tolerances and superior surface finishes to function effectively. In drilling operations, for example, the precision of these parts can directly impact the speed and safety of the process.

The honing process is particularly critical for ensuring that bores are perfectly round and smooth, which is essential for pistons and other hydraulic components. This precision ensures optimal performance and prevents premature wear and tear.

Technological Advancements in Honing

Recent advancements in honing technology have further enhanced its role in oil and gas component fabrication. The development of automated honing machines and advanced abrasives has increased the precision and efficiency of the process. These innovations allow for tighter tolerances and improved surface finishes, which are essential for modern oil and gas applications.

Additionally, the integration of computer numerical control (CNC) in honing machines has enabled manufacturers to produce complex geometries with high accuracy. This technological progress has made it possible to meet the increasingly stringent demands of the oil and gas industry.

Conclusion

In conclusion, precision honing plays a crucial role in the fabrication of oil and gas components. Its ability to enhance performance, improve durability, and ensure safety makes it an indispensable process in the industry. As technology continues to advance, the importance of precision honing will only grow, paving the way for more efficient and reliable operations in the challenging environments of the oil and gas sector.