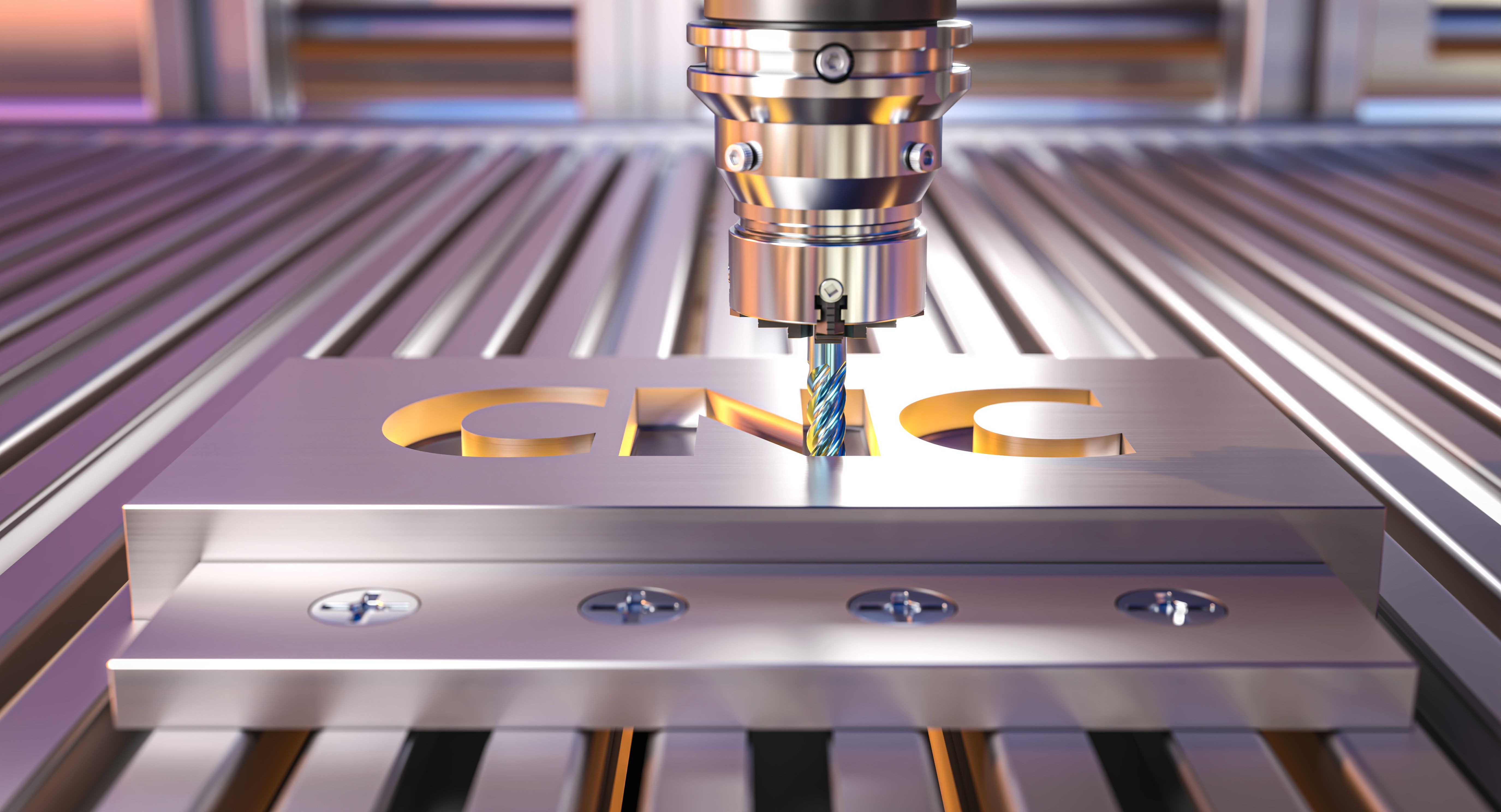

Precision CNC Machining for Wellhead Components

Understanding Precision CNC Machining

Precision CNC machining is a critical process in the manufacturing of wellhead components, which are essential for the efficient and safe extraction of oil and gas. This technology involves the use of computer-controlled machines to produce parts with high precision and accuracy. By leveraging advanced software and machinery, manufacturers can create complex components with tight tolerances, ensuring optimal performance in demanding environments.

The precision offered by CNC machining is unparalleled, making it a preferred choice for industries where accuracy is paramount. In the oil and gas sector, wellhead components must withstand extreme pressures and temperatures, necessitating the use of robust materials and precise manufacturing techniques. CNC machining provides the reliability required to meet these stringent standards.

The Role of Wellhead Components

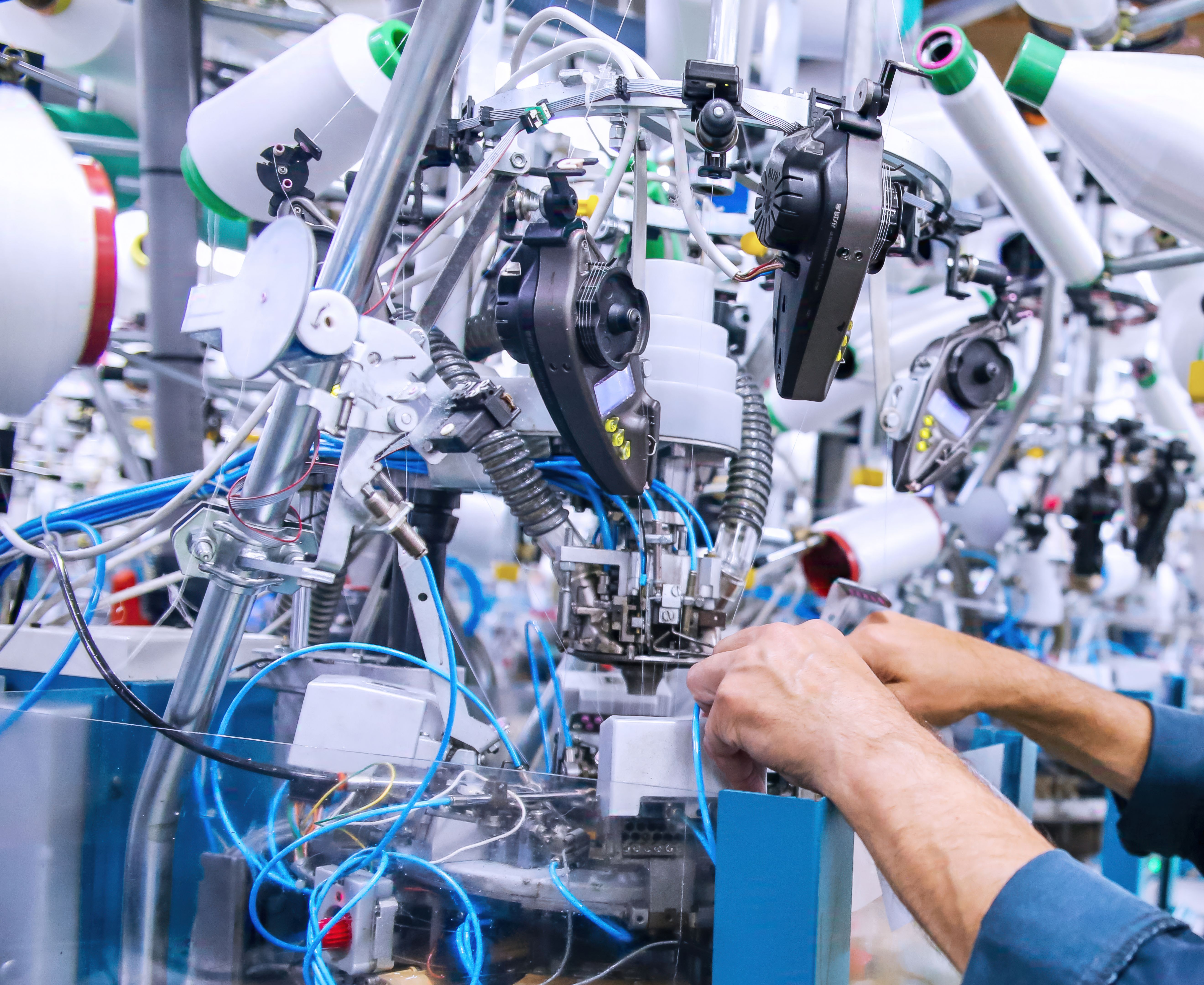

Wellhead components play a crucial role in controlling the pressure and flow of oil and gas from wells. These components are part of a larger system that ensures the safe and efficient extraction of resources. Key components include valves, spools, and flanges, each requiring meticulous fabrication to function correctly under harsh conditions.

Given the critical nature of these components, manufacturers must adhere to strict quality control measures during production. Any deviation from specified dimensions can lead to operational failures, posing significant safety risks. Therefore, precision CNC machining is indispensable in producing wellhead components that meet industry standards.

Advantages of Precision CNC Machining

The adoption of precision CNC machining in the production of wellhead components offers several advantages:

- High Accuracy: CNC machines are programmed to execute precise movements, resulting in components that adhere closely to design specifications.

- Consistency: The automation of the machining process ensures uniformity across batches, minimizing variations between parts.

- Efficiency: With reduced manual intervention, CNC machining increases production speed and reduces lead times.

These benefits not only enhance the quality of the final product but also contribute to cost savings by reducing material waste and rework.

Materials Used in Wellhead Component Manufacturing

The choice of materials is crucial in the manufacturing of wellhead components, as they must endure extreme conditions. Commonly used materials include stainless steel, carbon steel, and various high-strength alloys. Each material offers unique properties that cater to specific requirements in terms of corrosion resistance, strength, and durability.

CNC machining allows manufacturers to work with a wide range of materials, offering versatility in component design. This capability ensures that each component is tailored to its intended application, contributing to the overall reliability of wellhead systems.

The Future of CNC Machining in Oil and Gas

The integration of emerging technologies such as artificial intelligence and machine learning is set to revolutionize CNC machining processes. By enhancing automation and predictive maintenance, these advancements will further improve the efficiency and accuracy of manufacturing wellhead components.

Moreover, as the demand for energy resources continues to grow, the need for reliable wellhead systems will become increasingly critical. Precision CNC machining will remain at the forefront of manufacturing innovations, driving improvements in performance and safety within the oil and gas industry.